PST-100

A new paradigm of civil engineering

What is Soil Stabilizer?

*The developer, inventor, and patent holder (intellectual property rights) of the product names PST-100, USM-100, USH-100, ESS-100, PSC-100, and GIANTMX-100 is BYUN HO DEOK, the C.T.O of IT’s ST Co., Ltd.

Benefits of PST-100

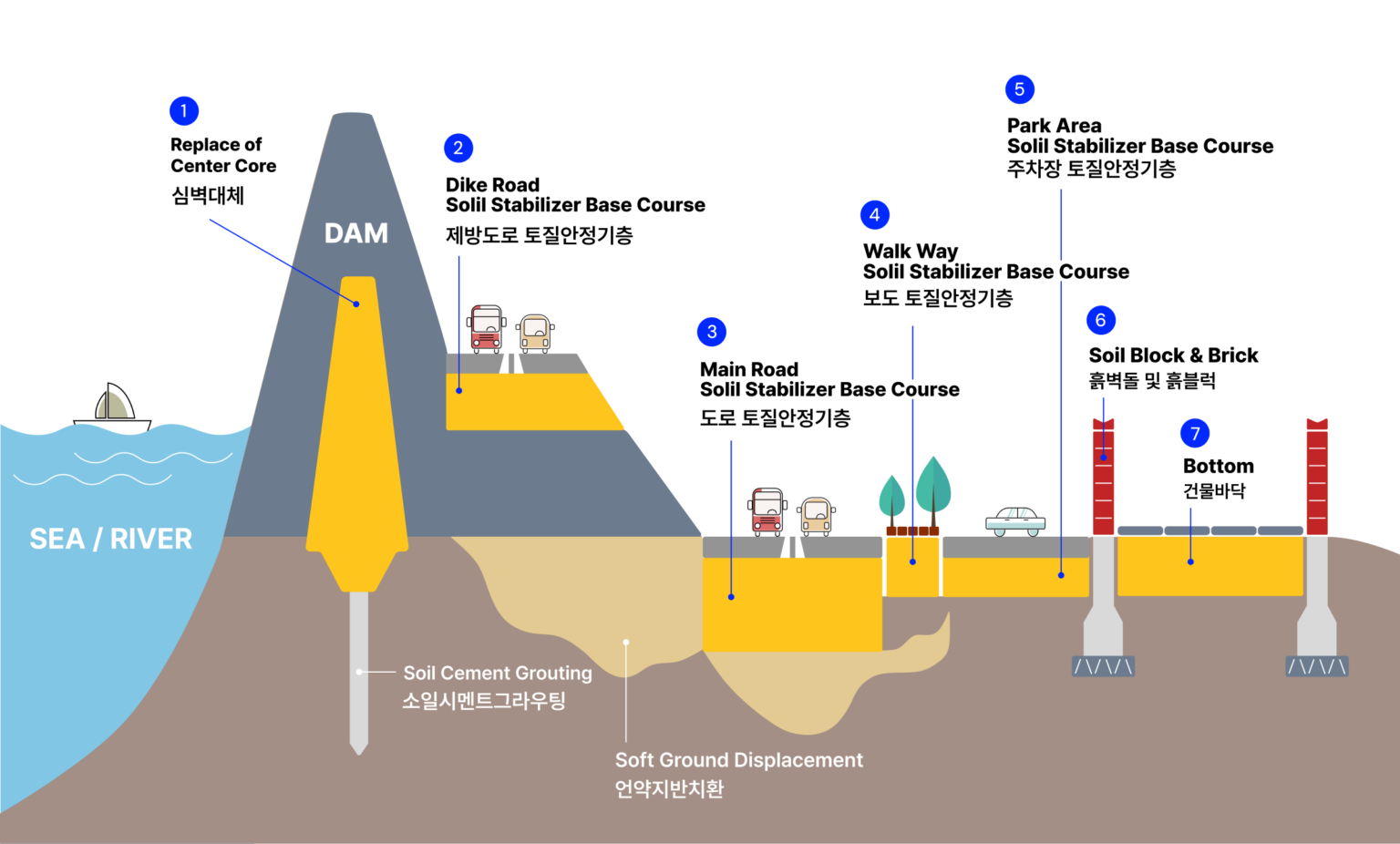

Vs. Existing Construction Method

- Compared to existing construction methods, the construction period is shortened by 1/3 and construction costs are reduced by more than 30%.

- Uses soil around the construction site. In other words, mixed crushed stone, which is the main material for the base layer and sub-base layer in the existing road construction method, is not used.

- For no stone is used, quarrying costs and stone transport costs are eliminated.

- Eliminates environmental destruction factors caused by quarrying.

- A smaller amount of cement is used than that used in existing road construction methods.

- Road construction is possible with simple laying, mixing, and compaction equipment.

- Since acts like a concrete plate, the selective layer of existing construction methods is not necessary.

- Since the base course, sub-base course, and selective layer are replaced by a soil stabilization layer, the construction cross section is reduced.

PST-100 Vs. Other Soil Stabilizers

Eco Friendly

In the case of PST-100, a very small amount of cement (150kg) is used per 1m3 (soil unit weight:1,700 kg/m3). This amount of cement corresponds to 8.9% of the weight of soil.

This amount of cement corresponds to 8.9% of the weight of soil.

Other soil stabilizers mainly use adhesives instead of cement, and in particular, they are unsuitable for the environment because they use polymer-based or volatile bonds.

Cost Effective

Other soil stabilizers require a larger amount compared to PST-100.

– PST-100 requires only 0.088% of the soil weight (soil unit weight: 1,700 kg/m3), but other soil stabilizers require a very large amount of about 3 to 6%.

– Other soil stabilizers use expensive products such as polymers and volatile bonds to bind particles, which increases product costs.

Easy to use

PST-100 is easy to handle on site because the powder is diluted in water and used immediately.

However, other products are liquid products or heterotype that mix two or more ingredients, so it is inconvenient to manufacture and use them immediately on site, and some products are volatile and can only be handled by very limited technicians.

Basis for Use of

Domestic Soil Stabilizers

* Transitional Measures for the Establishment of Guidelines: These guidelines may be applied from the time of publication. For ongoing design services or construction projects, they may be applied if deemed necessary by the head of the contracting agency.

2011 Road Pavement Integrated Guidelines (November 2011, Ministry of Land, Infrastructure, and Transport)

Page 83: II. Pavement Substructure / Page 111: 3. Substructure Stabilization Treatment / Page 120: 3.1.8 Use of Other Materials

Road Pavement Substructure Construction Guidelines (April 2017, Ministry of Land, Infrastructure, and Transport)

Page 17: 4 Base Course / Page 19: 4. Base Course / Page 24: 4.2 Cement Stabilized Base Course

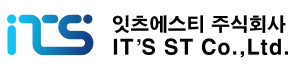

Application of Soil Stabilizer PST-100

The PST-100 can be applied across various fields of urban construction

- Base course of a highway

- Base course of main road

- Base course of walk way

- Base layer of Parking area

- Bottom of the building

- Replace of soft ground

- Block & Brick of soil

- Center Core of Dam

- Base course of bank road

Strength Standards for the Base Course and Subbase Course of Roads

The strength standards for the base course (foundation layer) and subbase course (sub-foundation layer) of highways and national roads in Korea are generally expressed in terms of compressive strength and elastic modulus. Below are the standards for the base course and subbase course of Korean roads, presented in SI units.

*When applying PST-100, it achieves approximately 1.5 times the uniaxial compressive strength specified in the Korean road design standards and specifications without using crushed stone (aggregate).

Base Course

The strength standard for the base course is mainly expressed in compressive strength.In Korea, the standard is denoted by CBR (California Bearing Ratio), and the CBR value of the base course must be at least 30. A CBR of 30 corresponds to a compressive strength of about 1 MPa or more.When using CBR as a reference, the compressive strength standard is generally 3 MPa or higher.

Subbase Course

The subbase course requires a CBR value of 10 or more, which generally corresponds to a compressive strength of about 2.5 MPa or higher.

Compressive Strength (SI units)

Compressive strength is measured in megapascals (MPa), where 1 MPa = 1 N/mm2.These standards are based on the Korean road design specifications and guidelines and are applied to the design and construction of highways and major roads.

Preparation and Curing Methods of Test Specimens

KS F2329 / Method for preparing and curing test specimens for compressive and bending strength tests of soil-cement in a laboratory.

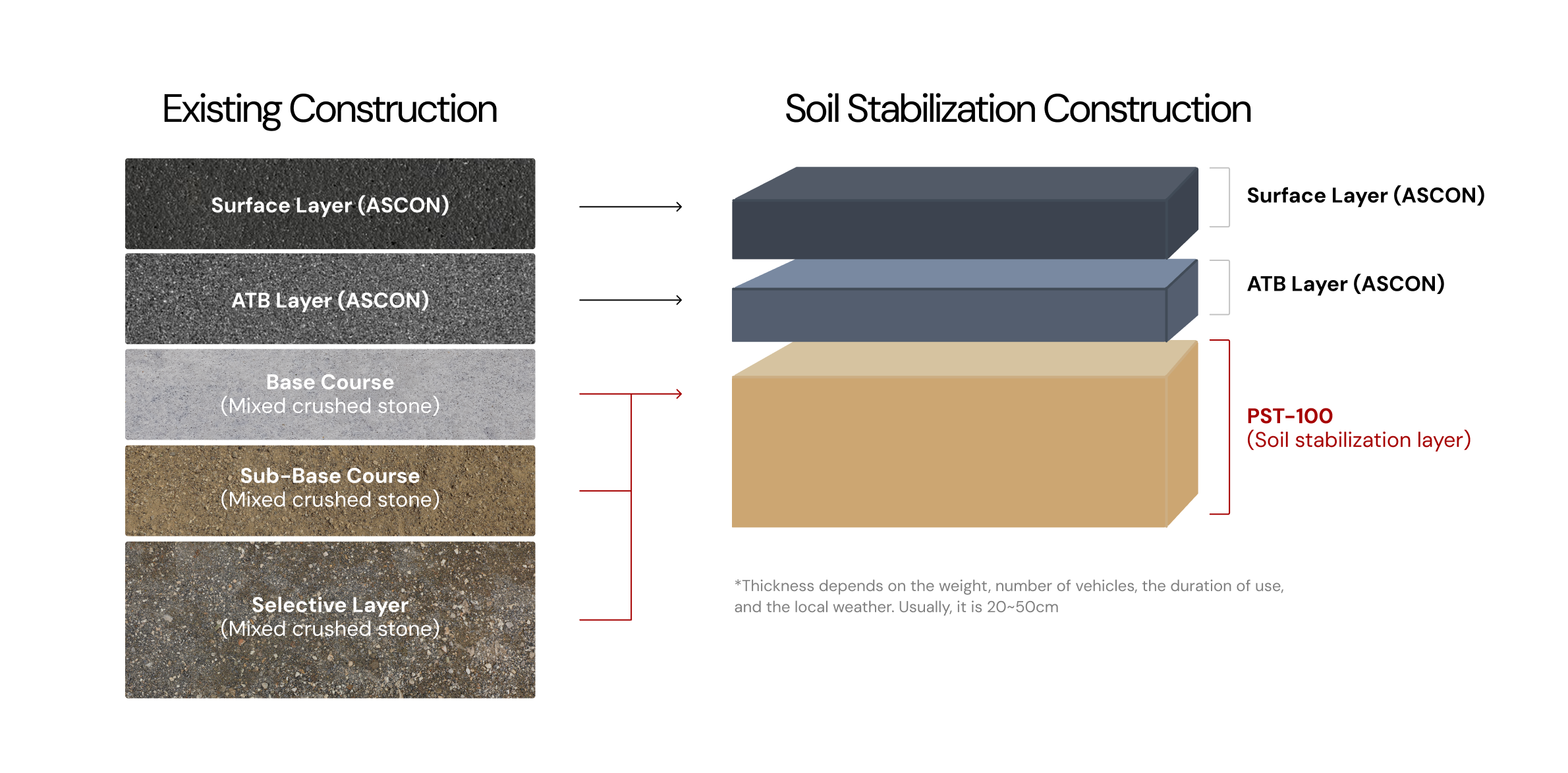

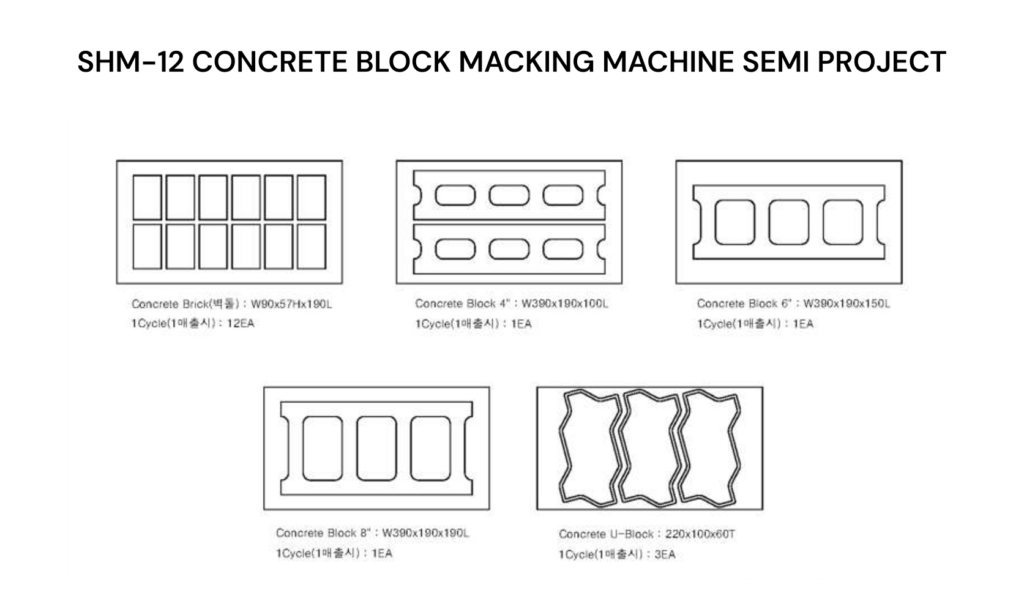

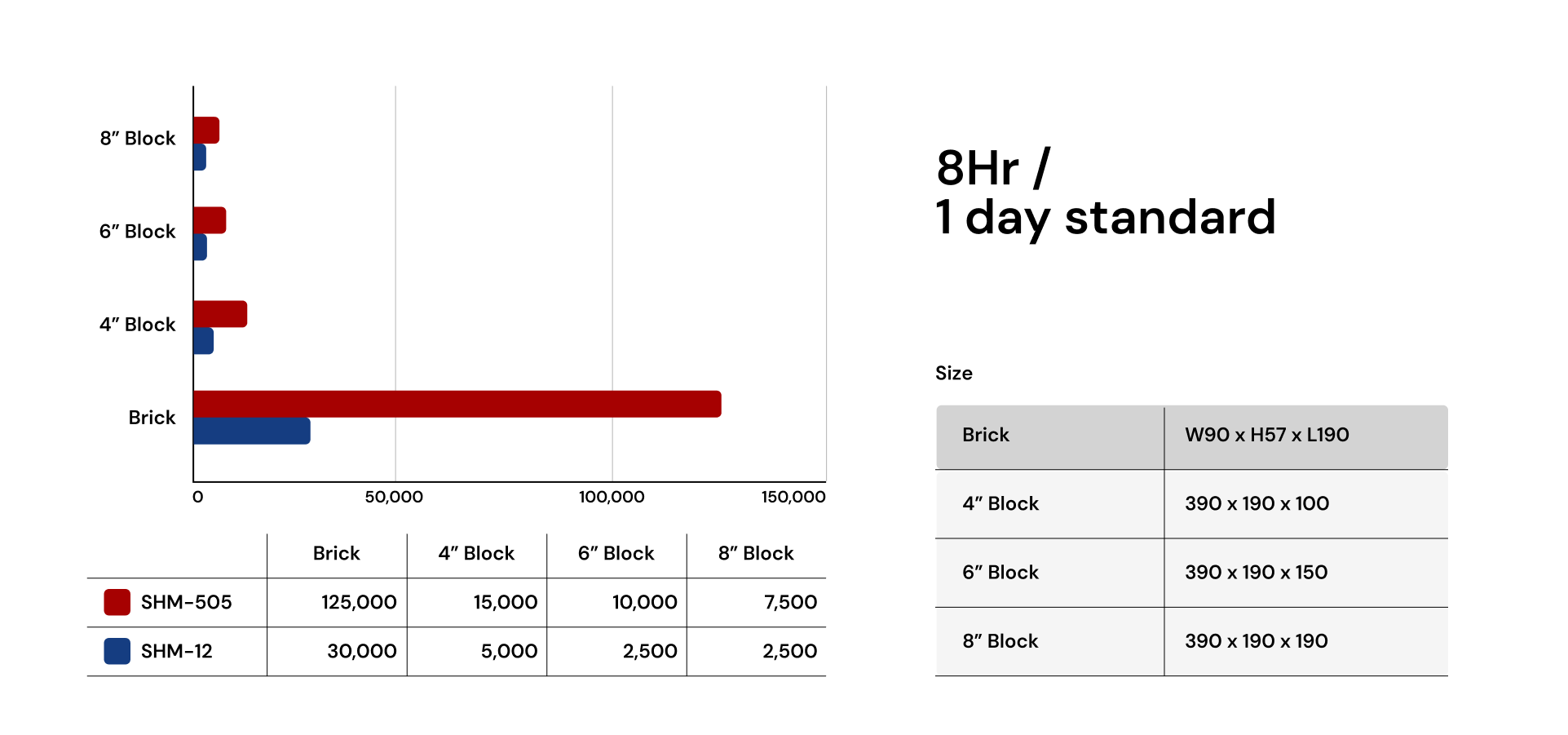

Soil Stabilizer for Bircks, Blocks & Retaining Walls

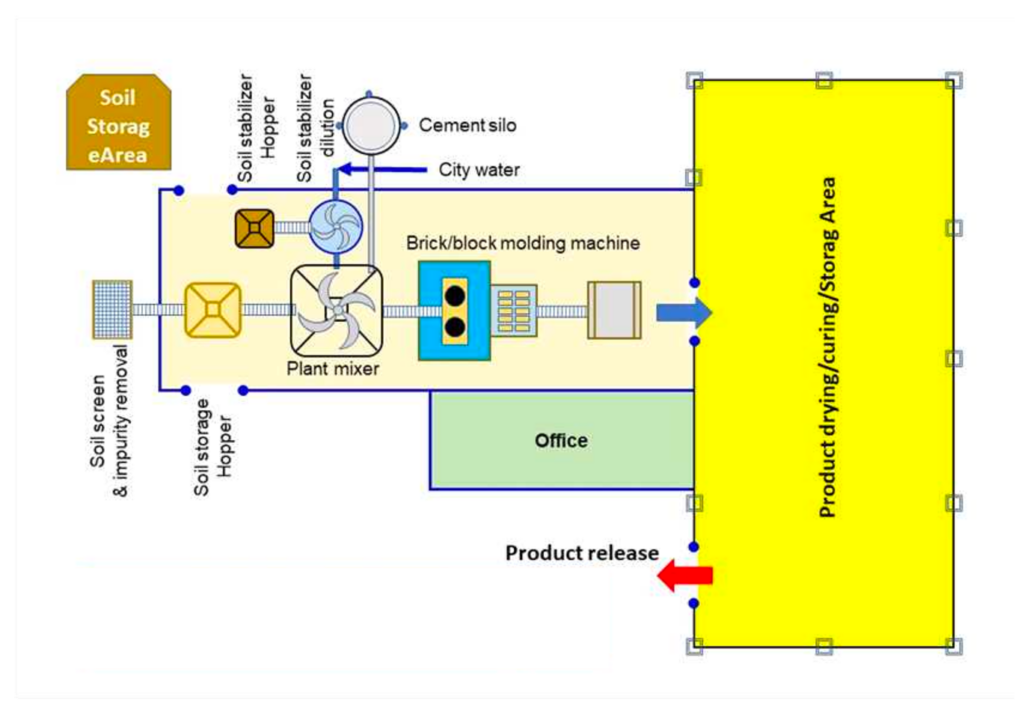

Business Overview

The brick industry in Southeast Asia and developing countries is one of the key industries driven by the growth of the construction sector and urbanization. As developing nations experience rapid economic growth and urban expansion, the demand for housing, commercial buildings, and infrastructure projects continues to increase. Consequently, there is a steady rise in demand for construction materials such as bricks.

Additionally, some countries frequently experience natural disasters such as floods due to tropical climates and monsoon effects. In post-disaster reconstruction, the materials used for rebuilding homes must be durable, cost-effective, and locally available.

Traditional brick manufacturing processes involve fuel consumption and heating, leading to severe environmental pollution due to smoke emissions. Moreover, conventional brick products often suffer from irregular sizes and poor quality.

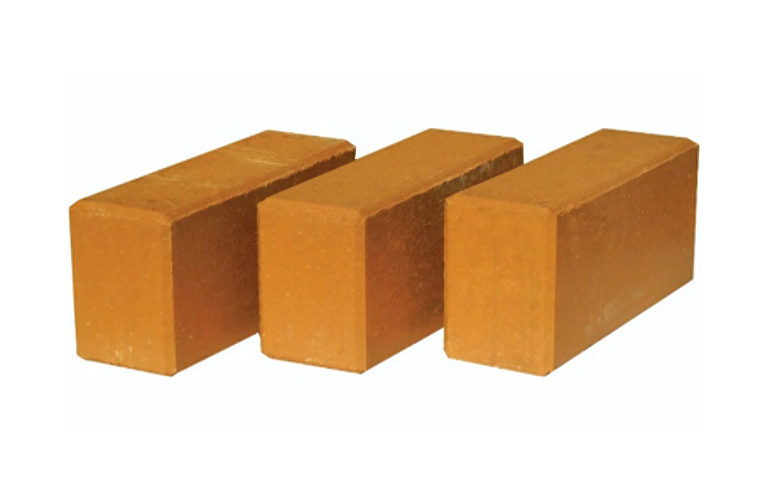

To address these issues, we propose using locally available soil and a soil stabilizer (patented in South Korea, Patent No. 10-1766219: "Solidification Composition, Solidified Body Using Solidification Composition, and Its Manufacturing Method") to produce non-fired bricks and blocks. This method eliminates carbon dioxide emissions and allows for the formation of bricks and blocks using soil stabilizers, making it possible to obtain carbon credits while producing environmentally friendly products.

Expected Effects of the Business

Solving air pollution issues : Prevents environmental pollution caused by firing raw materials during brick production.

Addressing fuel and raw material supply challenges : Uses locally available soil near production facilities without the need for high-energy firing. Encouraging conversion of traditional brick factories : Persuading existing brick manufacturers to establish new factories utilizing soil stabilizers. Government incentives for greenhouse gas reduction : Enabling governments to acquire carbon credits by reducing greenhouse gas emissions by 20,000– 30,000 tons per factory. Expanding applications in public infrastructure : Promoting the use of non-fired brick production with soil stabilizers in government road construction projects.

- Advantages of block / brick with PST-100

1.Acquiring urban development space through the downsizing of existing plants

2.Excellent thermal barrier effect

3.Strength:Stronger than cement bricks and red bricks.

4.No need fire block/brick in the kiln

5.Inexpensive :On-the-spot soil

- Soil brick

- Soil block / soil Sidewalk block

- Soil-Filled Reinforced Retaining Wall

- Soil-Based Water Channel Stabilized with PST-100

- Embankment Protection Block for Canals

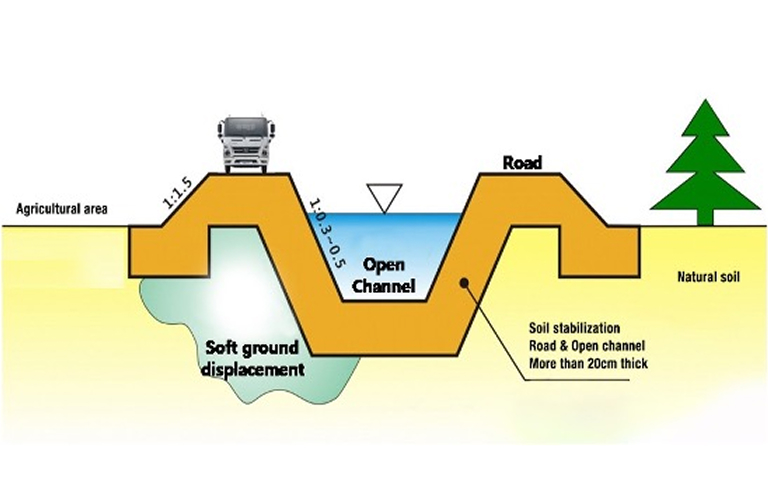

- General structure of open channel and road

Structure thickness :

- Bottom and slope of open channel: at least 20Cm

- Road: at least 20 cm

– Slope grade: in case of compaction natural soil should be 1: 1.5 or more, 1: 0.3 ~ 0.5 when soil stabilizer is applied

Compaction :

- bottom: 95% or more

- slope: 85% or more

- Road: 95% or more

– Treatment of rapid flow section : In order to prevent the piping phenomenon of the bottom and slope at the section of rapid flow or meandering, the non-woven fabric (for slope stability and soft ground reinforcement) is impregnated in the soil cement mixed with soil stabilizer and then applied to finished surface.

Soft ground replace ment: Replacement by mixing external soil with cement and soil stabilizer.

- Diagram of open channel and roads

Contact us

EMAIL : hdbyun@hanmail.net / hdbyun@gmail.com

ADRESS : ASK Tower 929, 37, Digital-ro 10-gil, Geumcheon-gu, Seoul, Republic of Korea

*The developer, inventor, and patent holder (intellectual property rights) of the product names PST-100, USM-100, USH-100, ESS-100, PSC-100, and GIANTMIX-100 is BYUN HO DEOK, the C.T.O of IT’s ST Co., Ltd.